The back is now attached to the sides and the box closed

|

The pencil markings are gone and fit should be perfect! I notch the sides

to accommodate the back braces. This way, the bracing never comes loose.

On the other hand, If id does come loose, it's a bit trickier to re-glue.

But there are tools for that too, so not to worry... |

|

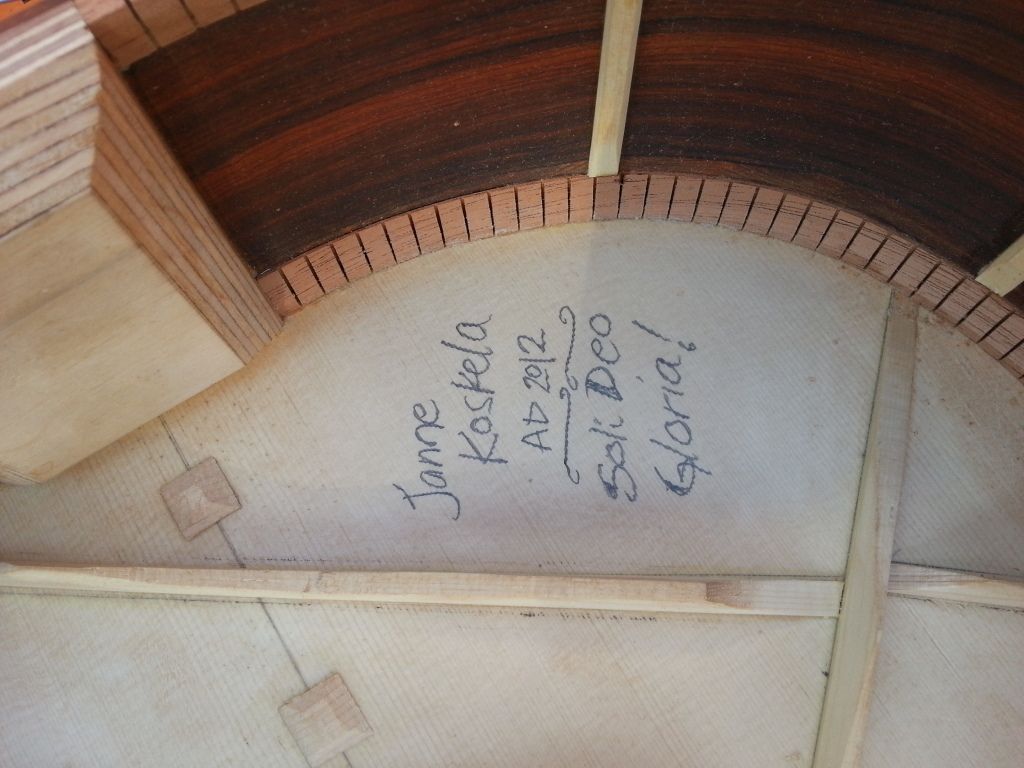

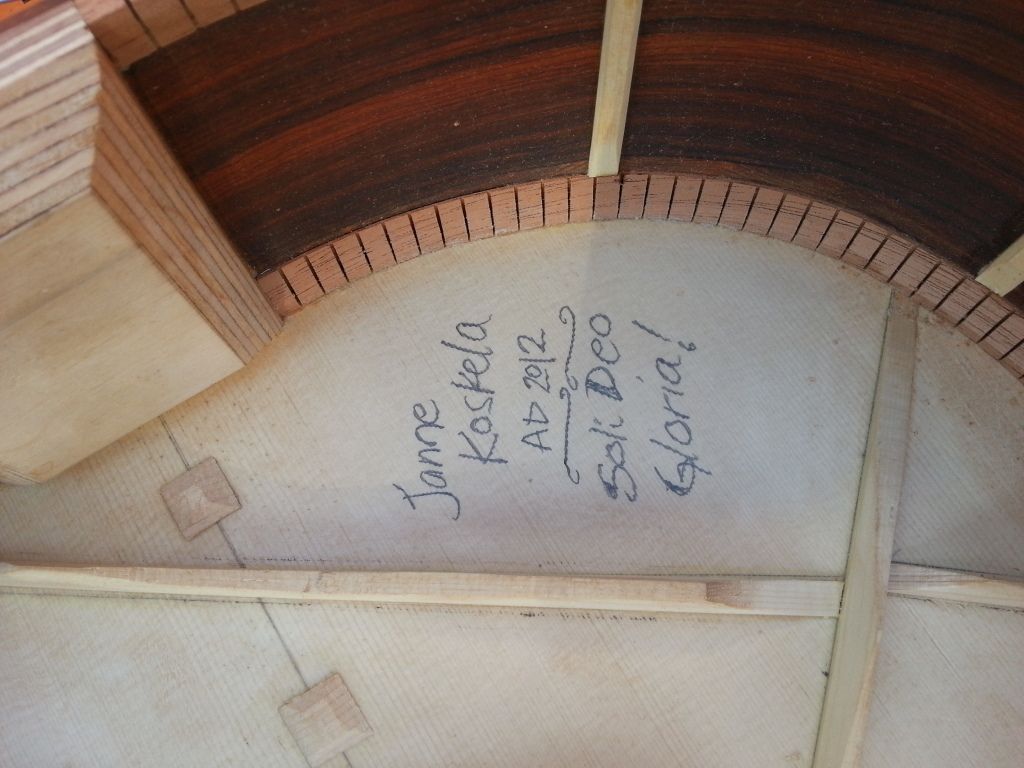

A little message, should somebody ever open the box again.

The little squares are there to reinforce the center seam

agains any splitting. |

|

Applying the glue with a very sophisticated high tech

tool I got from my parents some 35 years ago.

The end block is angled so that the gluing surface is approximately

the same as that of the kerfing's |

|

Lots of clamps, but only gentle force, since everything fits

together like a fist in the eye (like we say in Finnish) |

|

I cut the overhang of the top and back using my handy

router setup. It's easy, fast and foolproof.

Below is a little video of the setup in practice.

The sound of the router is one of the nastiest in the industry... |

|

Freshly trimmed back in the morning sun.

I wouldn't mind looking at it every day. |

|

| The top before the bevel is trimmed |

|

...and the still fuzzy bevel area in detail. There will be flamed maple

binding extension to cover the insides here. The top was trimmed

using traditional and oh, so sharp knife. |

By the way, working with cocobolo you may get hurt. Cocobolo sawdust in my eye is the only explanation I could come up with, as I woke up with black and swollen eye. Shouldn't have spoken about the fist in the eye in the first place. This punch got in!

2 kommenttia:

Hitsit, pohja pomppasi lliimauksista. Cocobolo on öljyineen tosi ikävää ainetta saada liimatuksi. Seuraavaksi kokeilen kaksikomponenttiliimaa.

http://www.wood-database.com/wood-articles/gluing-oily-tropical-hardwoods/

Lähetä kommentti